Why plastic injection method?

If you’re reading this, you probably know a thing or two about plastic injection molding. There are many reasons why the injection molding process is so popular in the field of plastic manufacturing. The most common reason is that this machine is the best tool for producing large and uniform quantities of plastic parts. There are many different types of molding machines, the choice of which one depends on what you are producing and how the machine will affect the product.

Plastic injection machine process

Injection molding is the most practical production process for making all kinds of plastic parts. A wide variety of products are produced using this method, which differ from each other in terms of size, complexity and application. In the process of plastic injection, a variety of plastic compounds such as polycarbonate, polystyrene, polyethylene, polypropylene, polyvinyl chloride, acrylic and Teflon are used to produce the final product.

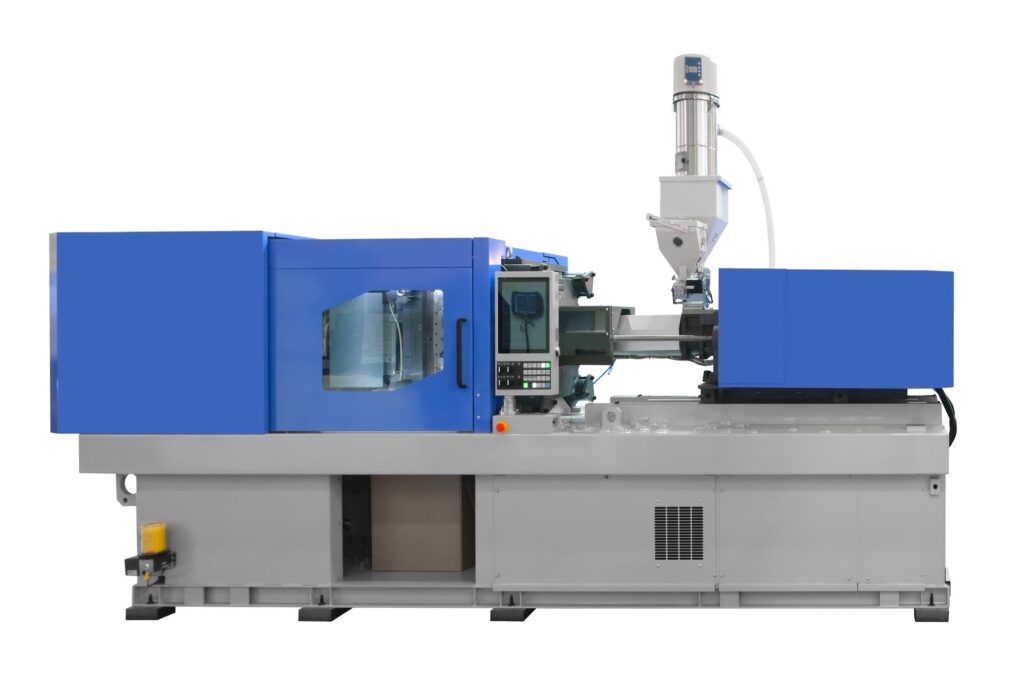

Mechanism of plastic injection machine

The edges of the injection molding machine can be closed horizontally or vertically. Most machines are closed horizontally, but vertical injection machines are used in some applications, such as molding and construction, which allow the machine to use gravity. Some vertical devices also do not need to close the mold.

There are many ways to fasten to the screen, the most common of which are hand clamps (both halves are screwed to the screens). However, hydraulic clamps (chokes are used to hold the tool in place) and magnetic clamps are also used. Magnetic and hydraulic clamps are used in cases where quick tool change is required.

The plastic injection machine is divided into 2 parts: the first part is the clamp and the second part is the injection part.

The function of the clamp unit is to open and close the mold and eject the products. There are 2 types of opening and closing methods, the mechanism of this device is that first in the clamp section (circular section in the figure below), the clamp is opened and closed manually and then in the mold injection section directly with a hydraulic cylinder.